EcoBoost is a marketing name for turbocharged, direct-injection petrol engines produced by Ford and originally co-developed by German company FEV Engineering. EcoBoost-equipped engines are designed to deliver power and torque consistent with those of larger-displacement (cylinder volume), naturally aspirated engines, which Ford claims can achieve about 30% better fuel efficiency and 15% fewer greenhouse emissions. Ford sees the EcoBoost technology as less costly and more versatile than further-developing or expanding the use of hybrid and diesel engine technologies.

The 2.7L EcoBoost engine is built at the Lima (Ohio) Ford Engine Plant. Ford has invested half a billion dollars in the Lima plant for the new engine.

Ford introduced the twin-turbo 2.7L EcoBoost engine with the 2015 Ford F-150. It delivers 325 hp and 375 lb⋅ft torque. Being a next-generation design, it uses compacted graphite iron, a material Ford uses in its 6.7 L PowerStroke diesel engine. As of 2018 the 2.7L has been upgraded with the most prominent change being the addition of port fuel injection. Ford claims that horsepower is unchanged at 325 while torque is boosted 25 lb-ft to 400 lb-ft.

Power Ratings:

- 2015-2017 Ford F-150 – 325 hp @ 5750 rpm, 375 lb⋅ft @ 3000 rpm

- 2018 Ford F-150 – 325 hp @ 5000 rpm, 400 lb⋅ft @ 2750 rpm

2.7L EcoBoost F-150 Specs & Info:

- 325 HP & 375 TQ

- 18 mpg city / 23 mpg highway / 20 mpg combined

- 2,250 lbs Payload Rating / 8,500 lbs Towing Capacity

- Direct Fuel Injection

- Dual Over Head Camshafts

- Engine block is cast from the same material as the 6.7L Power Stroke Diesel

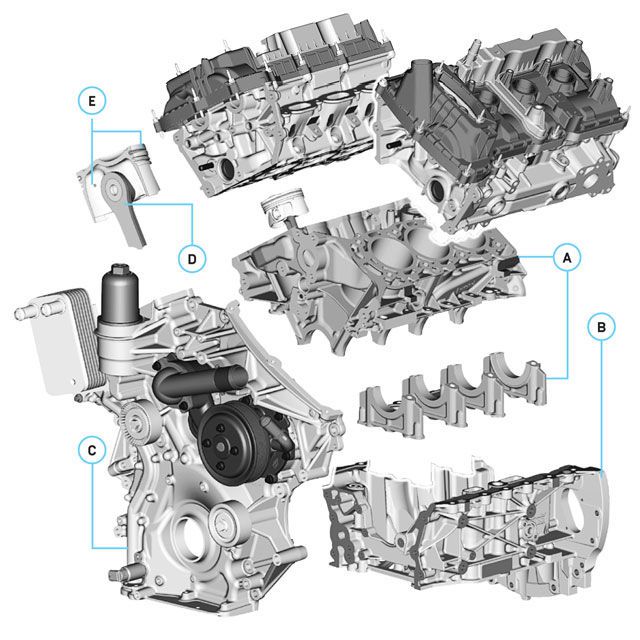

A. Upper Block

The most novel element of this engine is the two-piece block, with a single iron casting for the upper block, which includes the cylinders, and the main bearing caps (only the lower half of the block is aluminum). The bearing caps are laser etched and then cracked off to fit the crankshaft. Once reassembled, the three-dimensional mating surface for each cap provides extra stability. The match is so good that Ford has tested engines running without the caps bolted in at all.

B. Lower Block

Most engine blocks are made from a single material, but to save weight the 2.7-liter’s lower ladder frame is die-cast aluminum and bolts onto the iron upper half. A second set of bolts secures the bearing caps to the ladder frame to further stiffen the engine. A composite oil pan seals up the bottom.

C. Integrated Front Cover

The IFC (no, not the cable channel) acts as a structural member that connects the major components of the engine. With its integrated water pump, oil passages for cam phasing, oil cooler, oil filter, and accessory drive components, the IFC arrives at the plant preassembled, streamlining the production process.

D. Piston Rods

Piston connecting rods have two ends—a big end that connects to the crankshaft and a small end that connects to the piston. The small end normally has a bushing, but Ford eliminated this by honing the wrist-pin hole and applying a high-durability coating along with optimizing the shape for better oil distribution. Removing the bushing not only saves money but also reduces the engine’s overall height.

E. Piston-Ring Seats

There is a steel insert in each aluminum piston for the top oil ring to improve durability—a trick swiped from semi-truck engines. The engine also uses a tactic often seen in F1: Small holes in the lowest ring seats allow oil to escape to the crankcase, which minimizes drag from oil buildup at high speeds.

Stop/Start

This will be the first Ford truck engine with automatic stop/start capability. To prevent durability problems resulting from oil starvation every time the engine starts,a proprietary friction-reducing coating is applied to the main bearing races. A lifetime-wear test using dirty oil revealed almost no abrasion on the coated surface.

Improving Performance:

The 3.5L EcoBoost offers a good bit of power and acceleration out of the factory, however, it can benefit from some simple mods that will improve overall performance.

Use High Octane – For those who are unaware, the 2.7 Ecoboost requires 87 octane fuel, but the owners manual suggests premium fuel for severe duty usage such as trailer towing.

The EcoBoost has a factory “auto octane adjustment” feature present in the ECU. This feature allows the ECU to self-adjust according to the type of fuel being used (be it 87, 90 or 93 octane, etc.). You can get the best performance from your 3.5L EcoBoost by using the premium higher octane fuel.

Cold Air Intake – Upgrading your EcoBoost F-150 / Expedition’s cold air intake will allow it to take in more air, which will help the turbocharger work harder, produce more power, and also improve throttle response as well as fuel economy. Replacing your intake with a new cold air intake is generally good for an extra 10-20 horsepower, depending in its configuration.

Cat-Back Exhaust – A good cat-back (replaces everything from the catalytic converter back) exhaust should increase your horsepower by around 10-15 horsepower.

Tuner – You can also gain horsepower from a tuner such as this SCT Performance 5015P Livewire TS+ Performance Ford Programmer/Monitor.

Intercooler Upgrade – The intercooler reduces the temperature of the air being force in to the engine by the turbo. The cooler the air, the more horsepower it will produce. Upgrading to an intercooler that can reduce the temperature of the forced air, will lead to more horsepower.